Air adjustment on Beckett oil burners plays a crucial role in ensuring efficient combustion and optimal burner performance. Understanding the principles of air adjustment and its impact on burner operation is essential for maintaining a well-functioning heating system.

This comprehensive guide delves into the intricacies of air adjustment on Beckett oil burners, providing detailed instructions, troubleshooting tips, and advanced techniques to maximize burner efficiency and longevity.

Air Adjustment Theory

Air adjustment in oil burners is a crucial process that optimizes combustion efficiency and burner performance. It involves regulating the amount of air supplied to the burner, ensuring proper mixing of fuel and air for efficient combustion.

Role of Air in Combustion Efficiency, Air adjustment on beckett oil burner

Air plays a vital role in the combustion process of oil burners. It provides the oxygen necessary for the fuel to burn efficiently. The correct air-to-fuel ratio is essential for complete combustion, which minimizes fuel waste and reduces harmful emissions.

When air supply is insufficient, incomplete combustion occurs, resulting in soot formation, carbon monoxide production, and reduced heat output. Conversely, excessive air supply can lead to wasted energy, increased flame temperature, and potential damage to the burner components.

Beckett Oil Burner Air Adjustment

Beckett oil burners require proper air adjustment to ensure efficient combustion and optimal performance. Adjusting the air intake allows for fine-tuning the fuel-to-air ratio, resulting in improved fuel efficiency, reduced emissions, and a cleaner burn.

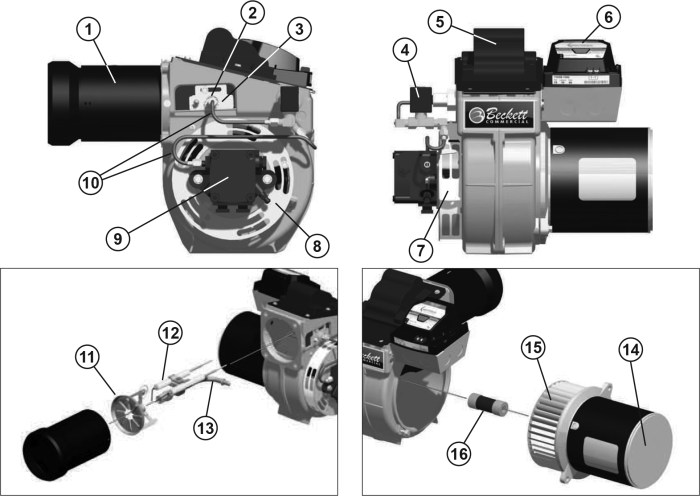

Air Adjustment Screw

The air adjustment screw is typically located on the burner’s air intake assembly. It controls the amount of air entering the combustion chamber by regulating the opening of an air damper. Turning the screw clockwise reduces the air intake, while turning it counterclockwise increases the air intake.

Air Adjustment Procedure

To adjust the air on a Beckett oil burner:

- Start by observing the flame through the sight glass. An ideal flame is bright blue with a slight yellow tip.

- If the flame is too yellow or smoky, it indicates insufficient air. Turn the air adjustment screw counterclockwise to increase the air intake.

- Conversely, if the flame is too blue or weak, it suggests excess air. Turn the air adjustment screw clockwise to reduce the air intake.

- Continue making small adjustments until the flame appears bright blue with a slight yellow tip.

Proper air adjustment is crucial for maintaining optimal burner performance and efficiency. Regular adjustment ensures a clean burn, reduces fuel consumption, and extends the life of the burner.

Common Air Adjustment Issues

Improper air adjustment on Beckett oil burners can lead to several common problems that affect the burner’s performance and efficiency. These issues can manifest in various ways, and understanding their causes and symptoms is crucial for effective troubleshooting and resolution.

Excessive Smoke

- Cause:Insufficient air supply

- Symptoms:Black or gray smoke emitted from the burner, soot buildup on the burner nozzle and combustion chamber

Sooting

- Cause:Incomplete combustion due to insufficient air supply

- Symptoms:Soot accumulation on the burner nozzle, combustion chamber, and flue pipe

Flame Instability

- Cause:Incorrect air-to-fuel ratio

- Symptoms:Yellow or flickering flame, burner cycling on and off, pulsating flame

Poor Fuel Efficiency

- Cause:Incorrect air-to-fuel ratio

- Symptoms:Increased fuel consumption, reduced heat output, higher emissions

Burner Lockout

- Cause:Insufficient air supply

- Symptoms:Burner shuts off prematurely, ignition failure, flame sensor activation

Troubleshooting and Maintenance

Air adjustment issues can arise over time due to factors such as wear and tear, fuel quality, and environmental conditions. Proper troubleshooting and regular maintenance are crucial to ensure optimal burner performance and prevent potential problems.

To effectively troubleshoot air adjustment issues, a systematic approach should be followed, involving the following steps:

- Inspect the burner:Visually inspect the burner for any signs of damage, loose connections, or blockages.

- Check the fuel supply:Ensure that the fuel supply is adequate and free of contaminants.

- Adjust the air damper:Make small adjustments to the air damper and observe the flame pattern. Adjust until the flame is blue and stable.

- Monitor the combustion efficiency:Use a combustion analyzer to measure the combustion efficiency and ensure it meets the manufacturer’s specifications.

Regular maintenance is essential to prevent air adjustment issues and maintain optimal burner performance. A maintenance schedule should include:

- Annual air adjustment check:Have a qualified technician perform an air adjustment check to ensure proper combustion and efficiency.

- Regular cleaning:Clean the burner nozzle, air filter, and other components to remove any buildup or debris.

- Filter replacement:Replace the air filter regularly to prevent dirt and debris from entering the burner.

Tools and Equipment

Proper air adjustment on Beckett oil burners requires the use of specific tools and equipment to ensure accurate and efficient results. These tools include:

- Combustion Analyzer:A device that measures the levels of oxygen, carbon dioxide, and other gases in the combustion process, providing insights into the air-to-fuel ratio and overall combustion efficiency.

- Manometer:A tool that measures pressure, particularly in the combustion chamber. It helps determine the pressure drop across the burner, which is crucial for proper air adjustment.

- Draft Gauge:A device that measures the draft or negative pressure in the combustion chamber. A proper draft is essential for efficient combustion and prevents smoke and soot formation.

- Air Adjustment Screw:A screw located on the burner assembly that allows for manual adjustment of the air intake. By turning the screw, the amount of air entering the burner can be regulated.

- Air Shutter:A movable plate or vane that controls the airflow into the burner. It can be manually adjusted to fine-tune the air-to-fuel ratio.

These tools are crucial for precise air adjustment, enabling technicians to optimize combustion efficiency, reduce emissions, and ensure the safe and reliable operation of Beckett oil burners.

Safety Precautions

Air adjustment on oil burners requires utmost caution to prevent potential hazards. Adhering to proper safety procedures is crucial to ensure the well-being of the technician and prevent equipment damage.

Before initiating any adjustment, the burner must be completely shut off and disconnected from the power source. Additionally, it is essential to allow the burner to cool down to avoid burns. The work area should be well-ventilated to dissipate any fumes or gases that may accumulate during the process.

Personal Protective Equipment (PPE)

- Safety glasses or goggles to protect the eyes from flying debris or chemical splashes.

- Work gloves to prevent cuts or burns from handling sharp or hot components.

- Appropriate clothing, including long sleeves and pants, to minimize exposure to potential hazards.

Safe Work Practices

- Always follow the manufacturer’s instructions and guidelines for the specific burner model.

- Never attempt to adjust the air while the burner is operating.

- Use only approved tools and equipment for adjustments.

- Inspect the burner thoroughly for any signs of damage or wear before making adjustments.

- After completing adjustments, double-check all connections and settings to ensure proper operation.

Additional Considerations: Air Adjustment On Beckett Oil Burner

Air adjustment is a critical aspect of oil burner maintenance and optimization. However, several factors can affect the accuracy and effectiveness of air adjustment, and these must be considered to ensure optimal burner performance and efficiency.

Fuel Quality

The quality of fuel used in the burner can impact the air adjustment process. Different fuel grades have varying combustion characteristics, requiring adjustments to the air supply to achieve optimal combustion. For instance, lower-grade fuels may require more air for complete combustion, while higher-grade fuels may require less air to avoid over-firing and soot formation.

Burner Type

The type of burner used also influences the air adjustment process. Different burner designs, such as pressure-atomizing or air-atomizing burners, have specific air requirements for efficient combustion. Pressure-atomizing burners typically require more air than air-atomizing burners due to the higher air pressure used in the atomization process.

Advanced Techniques

Advanced techniques for optimizing air adjustment in specific scenarios require a thorough understanding of the combustion process and the burner’s design parameters. These techniques involve precise adjustments to the air damper and fuel metering to achieve optimal combustion efficiency and minimize emissions.

One advanced technique is the use of a combustion analyzer to measure the flue gas composition and adjust the air supply accordingly. This allows for precise control of the air-to-fuel ratio, resulting in improved combustion efficiency and reduced emissions.

Case Study: Optimizing Air Adjustment for High-Efficiency Burners

In high-efficiency burners, precise air adjustment is crucial to achieve the desired combustion efficiency. By utilizing a combustion analyzer, technicians can measure the flue gas composition and adjust the air damper to maintain an optimal air-to-fuel ratio. This optimization leads to improved combustion efficiency, reduced emissions, and increased energy savings.

FAQ Corner

What is the purpose of air adjustment on an oil burner?

Air adjustment controls the amount of air supplied to the burner, ensuring optimal combustion and minimizing soot and carbon buildup.

How do I know if the air adjustment on my Beckett oil burner needs to be adjusted?

Signs of improper air adjustment include inefficient combustion, poor flame quality, and increased soot production.

What tools do I need to adjust the air on my Beckett oil burner?

You will typically need a screwdriver or Allen wrench, depending on the model of your burner.

Can I adjust the air on my Beckett oil burner myself?

Yes, air adjustment is a relatively straightforward procedure that can be performed by homeowners with basic mechanical skills. However, it is important to follow the manufacturer’s instructions carefully and ensure that all safety precautions are taken.