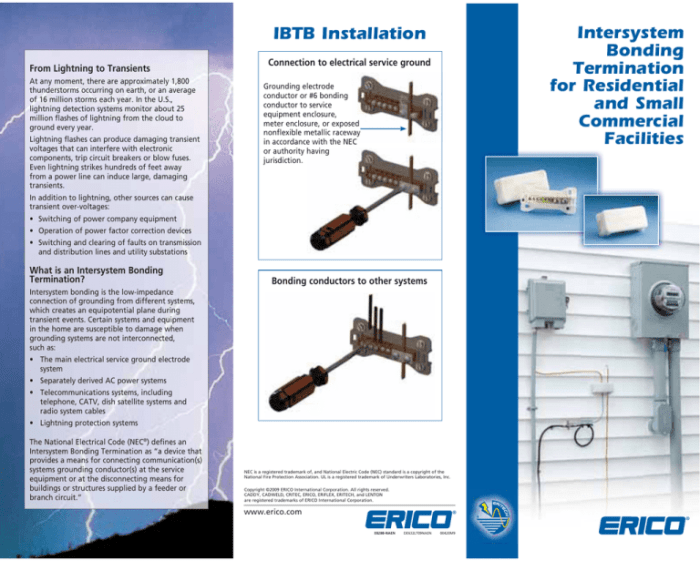

The intersystem bonding termination shall form a low-resistance path between the metallic enclosures of interconnected equipment and the grounding system to minimize voltage differences between interconnected equipment enclosures and to facilitate the flow of fault current.

This guide will provide an overview of the different types of intersystem bonding terminations, the methods used to terminate them, the design considerations that must be taken into account, and the testing and inspection procedures that are used to verify their integrity.

Intersystem Bonding Termination Types

Intersystem bonding terminations are used to connect two or more electrical systems together. There are three main types of intersystem bonding terminations: direct bonding, indirect bonding, and isolation bonding.

Direct bondingis the simplest type of intersystem bonding termination. It involves connecting the two systems together directly, without any intervening components. This type of termination is typically used for systems that are located close together and have similar electrical characteristics.

Indirect bondingis a more complex type of intersystem bonding termination. It involves connecting the two systems together through an intermediate device, such as a capacitor or a transformer. This type of termination is typically used for systems that are located far apart or have different electrical characteristics.

Isolation bondingis a type of intersystem bonding termination that is used to isolate two systems from each other. This type of termination is typically used for systems that are located in different buildings or that have different safety requirements.

Termination Methods

There are a variety of methods that can be used to terminate intersystem bonding. The most common methods include:

- Crimpingis a method of terminating intersystem bonding that involves using a crimping tool to compress a metal sleeve around the wire.

- Solderingis a method of terminating intersystem bonding that involves using a soldering iron to melt solder around the wire.

- Weldingis a method of terminating intersystem bonding that involves using a welding torch to melt the wire together.

The choice of termination method depends on a number of factors, including the type of wire, the size of the wire, and the environment in which the termination will be used.

Design Considerations

There are a number of design considerations that must be taken into account when selecting an intersystem bonding termination method. These considerations include:

- The type of wire: The type of wire that is used for intersystem bonding will determine the termination method that is used.

- The size of the wire: The size of the wire will determine the size of the termination that is used.

- The environment in which the termination will be used: The environment in which the termination will be used will determine the type of termination that is used.

By taking these considerations into account, it is possible to select an intersystem bonding termination method that will provide a safe and reliable connection.

Testing and Inspection

Once an intersystem bonding termination has been installed, it is important to test and inspect it to ensure that it is properly installed and functioning correctly. The following tests and inspections should be performed:

- Visual inspection: A visual inspection should be performed to ensure that the termination is properly installed and that there are no loose connections.

- Electrical test: An electrical test should be performed to ensure that the termination is conducting electricity properly.

- Mechanical test: A mechanical test should be performed to ensure that the termination is secure and will not come loose.

By performing these tests and inspections, it is possible to ensure that the intersystem bonding termination is properly installed and functioning correctly.

Industry Standards and Regulations, The intersystem bonding termination shall

There are a number of industry standards and regulations that govern the installation and maintenance of intersystem bonding terminations. These standards and regulations are designed to ensure the safety and reliability of intersystem bonding terminations.

The following are some of the most important industry standards and regulations that govern intersystem bonding terminations:

- IEEE Std 1100: IEEE Std 1100 is a standard that provides guidelines for the installation and maintenance of intersystem bonding terminations.

- NFPA 70: NFPA 70 is a code that provides requirements for the installation and maintenance of electrical systems. NFPA 70 includes requirements for intersystem bonding terminations.

- UL 486A: UL 486A is a standard that provides requirements for the construction and testing of intersystem bonding terminations.

By following these industry standards and regulations, it is possible to ensure that intersystem bonding terminations are properly installed and maintained, and that they will provide a safe and reliable connection.

FAQs: The Intersystem Bonding Termination Shall

What is the purpose of an intersystem bonding termination?

The purpose of an intersystem bonding termination is to provide a low-resistance path between the metallic enclosures of interconnected equipment and the grounding system.

What are the different types of intersystem bonding terminations?

There are two main types of intersystem bonding terminations: mechanical and electrical.

What are the advantages and disadvantages of each type of intersystem bonding termination?

Mechanical intersystem bonding terminations are more reliable than electrical intersystem bonding terminations, but they are also more expensive and difficult to install.